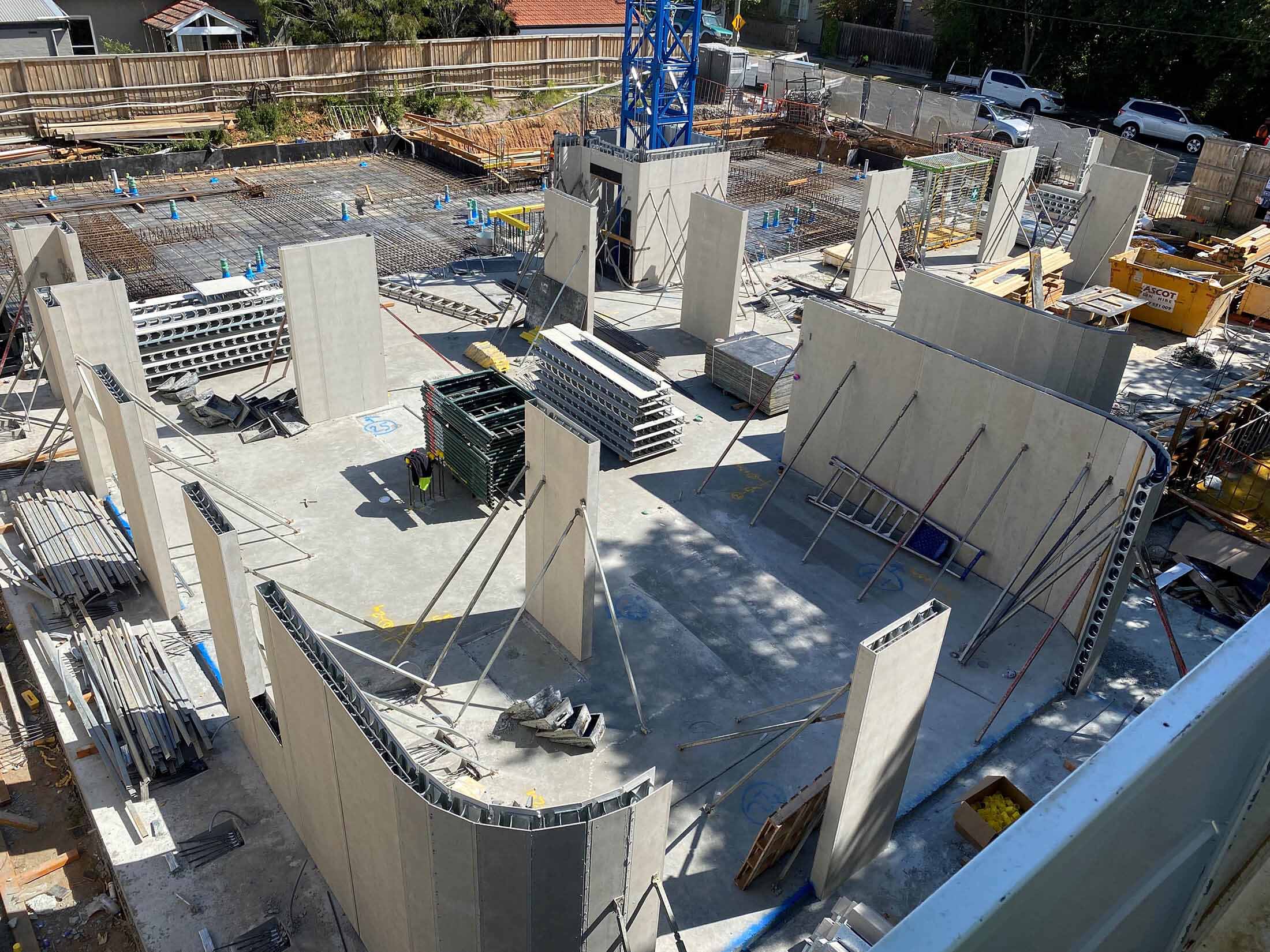

AFS Logicwall® is a fibre cement permanent formwork solution for internal and external concrete walling above-ground. Ideal for a myriad of multi-residential and commercial applications.

AFS Logicwall® is a system that provides load-bearing, fire and sound rated walls that can be tailored to suit most architectural and engineering demands.

Backed by CSR

Certified Australian-made

CodeMark Certified

BENEFITS

A quick construction and engineered solution in one

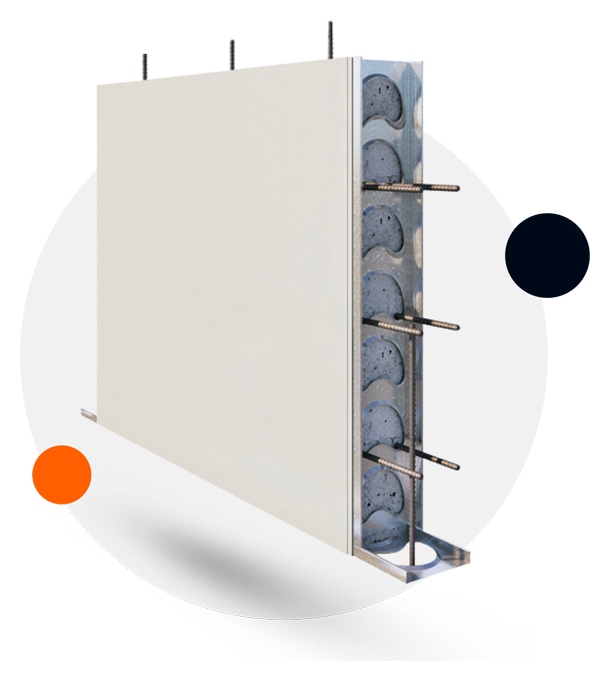

Each panel incorporates the functions of permanent sacrificial formwork, framework, and hard-wearing finish in one fast-to-erect solution. Once core filled with reinforced concrete it provides a structural load bearing walling system.

Certified and compliant

Tested and assessed by recognised peak Australian NATA registered test laboratories and major engineering consultancies, AFS Logicwall® can be shown to meet all critical building performance requirements.

For added peace of mind AFS Logicwall® is CodeMark Certified reinforcing that it complies with the relevant requirements of the National Construction Code (NCC) and confirms suitability for use in all NCC Class 1–10 buildings.

Minimal labour and handling

Reduce the costs of labour and handling, with lightweight AFS Logicwall® panels. There’s no need for cranes to install the panels. As individual panels can be erected by hand. Panels are then core-filled with easy-flow concrete in accordance with AFS Logicwall® concrete mix design specification.

Waste management

Our shop-drawn and custom-made-to measure AFS Logicwall® panels and delivered to site ready for installation, saving on waste and offcut disposal costs. The result is a massive reduction in onsite preparatory work, which drastically reduces the expense of skip bins, material waste and waste removal.

Quick delivery

Delivered in cut to measure lengths, AFS Logicwall® can be delivered to site within 8 business days of shop drawing approval.

Ready to finish

Eliminate the added expense of constructing stud and plasterboard finishing. AFS Logicwall® doubles as an excellent hard-wearing substrate for applied finishes such as skim coating, rendering, and painting.

If you’re looking for the most effective multi-application cost-saving permanent formwork for reinforced concrete walls, contact AFS today.

APPLICATIONS

Customised panels to suit your projects

Residential

Multi Residential

Office

Education

Healthcare

Aged Care

Stair shafts

- Ideal for installing reo-connecting bars into hollow panels before core-filling

- Continues internal load-bearing to external blade walls for increased efficiency

- Cost-effective and quick alternative to other methods

- Double reinforcement carrier

Balustrades

- Providing concealed slab edges where concrete walls for balustrades are specified

- An ideal solution where clean straight lines are essential

Blade walls

- Increased efficiency by continuing internal load bearing wall to external blade walls

- Provides clean straight lines and excellent substrate for render finishes

Internal party walls and corridor walls

- A standalone wall that is NCC compliant for structural, fire, and acoustic performance

- A solid reinforced concrete wall offering security and quality for the occupant

- Hard wearing durable substrate for finishing

- Minimum thickness for space utilisation

Façade walls

- Flat even surface for render finishes

- Excellent fibre-cement substrate with water block technology

Boundary Walls

- Ideal for difficult access for materials handling and finishing of walls

- Substrate provides clean finish even in a raw state

Profiles

Five panel profiles tailored to suit your requirements

Panels can be manufactured in any width from 200mm to 1100mm, and in any height from 2000 to 4200mm. Heights exceeding this can be supplied subject to a special order.

| Wall type | LW120 Single reinforcement |

LW150 Single reinforcement |

LW162 Single reinforcement |

LW200 Single reinforcement |

LW200D Double reinforcement |

LW262 Double reinforcement |

|---|---|---|---|---|---|---|

| Wall thickness | 120mm | 150mm | 162mm | 200mm | 200mm | 262mm |

| Filled wall mass | 290kg/m2 | 360kg/m2 | 394kg/m2 | 480kg/m2 | 480kg/m2 | 630kg/m2 |

| Application | Enternal façades, batten/sheet party walls, balus-trades |

Enternal façades, batten/sheet party walls, blade walls |

Stand-alone party walls, external facades, blade walls | Lift and stair shafts stand-alone party walls, blade walls | Deep beams lift & stair shafts, shear walls, blade walls | Shear walls, lift and stair shafts, blade wall |

| Acoustic rating (Rw) Rw + Ctr |

50 47 |

54 50 |

55 50 |

58 53 |

58 53 |

62 57 |

| Max fire resistance level Based on CSIRO testing |

240/240/180++ | 240/240/180++ | 240/240/240+ | 240/240/240+ | 240/240/240+ | 240/240/240+ |

| Design axial capacities* Based on AS3600-2018 |

320 kN/m~ | 415 kN/m^ | 555 kN/m^^ | 870 kN/m^^^ | 2055 kN/m# | 3460 kN/m# |

++ CSIRO testing, max fire load – 233 kN/m @ FI-FI = 3000mm

+ CSIRO testing, max fire load – 200 kN/m @FI-FI = 3000mm

~ Based on FI-FI = 2700mm, ecc < 0.05*tw’ k = 0.75, Hwe = 2025, f’c = 25 MPa, FRL 90/90/180

^ Based on FI-FI = 2700mm, ecc < 0.05*tw’ k = 0.75, Hwe = 2025, f’c = 32 MPa, FRL 90/90/180

^^ Based on FI-FI = 2700mm, ecc < 0.05*tw’ k = 0.75, Hwe = 2025, f’c = 32 MPa, FRL 120/120/240

^^^ Based on FI-FI = 2700mm, ecc < 0.05*tw’ k = 0.75, Hwe = 2025, f’c = 32 MPa, FRL 180/180/240

# Based on FI-FI = 2700mm, ecc < 0.05*tw’ k = 0.75, Hwe = 2025, f’c = 40 MPa, FRL 180/180/240

* Indicative capavities. Actual capacities to determined for specific wall location and design conditions.

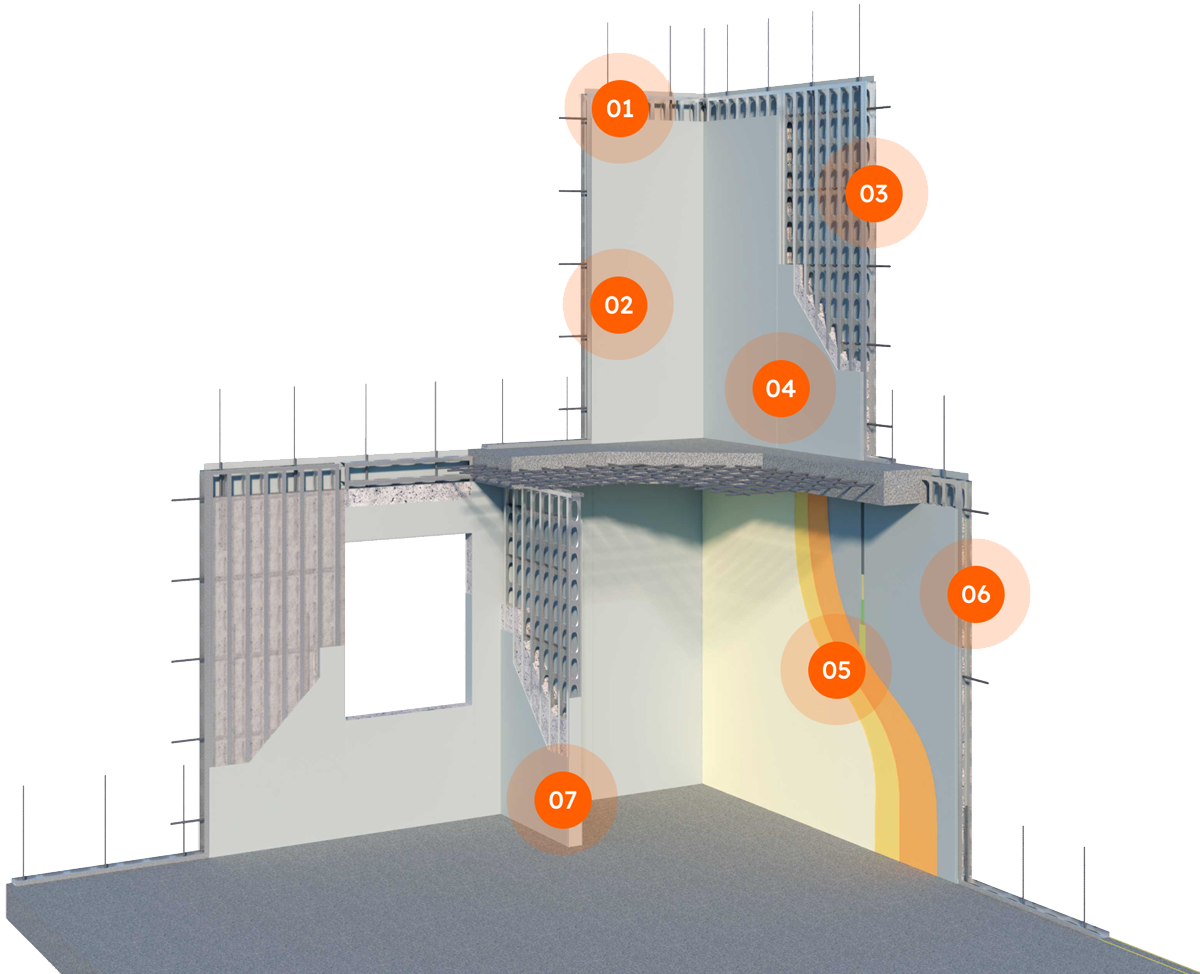

FEATURES

Multi-residential internal and external walling, easier materials handling, quicker completions

Prefabricated corner panel with factory installe horizontal reinforcing

Prefabricated corner panel with factory installe horizontal reinforcing

Site-installed reinforcing to engineer;s specifications

Site-installed reinforcing to engineer;s specifications

Upper level starter bars to engineer’s specifications

Upper level starter bars to engineer’s specifications

Recessed sheet edges for invisible jointing

Recessed sheet edges for invisible jointing

Internal/external coating systems (such as skim and texture coating, and paint finishes)

Internal/external coating systems (such as skim and texture coating, and paint finishes)

Horizontal reinforcing bars to engineer’s specifications

Horizontal reinforcing bars to engineer’s specifications

Assembles end cap at end of wall; blade wall panel for internal/external applications

Assembles end cap at end of wall; blade wall panel for internal/external applications

Construction Process