Start strong.

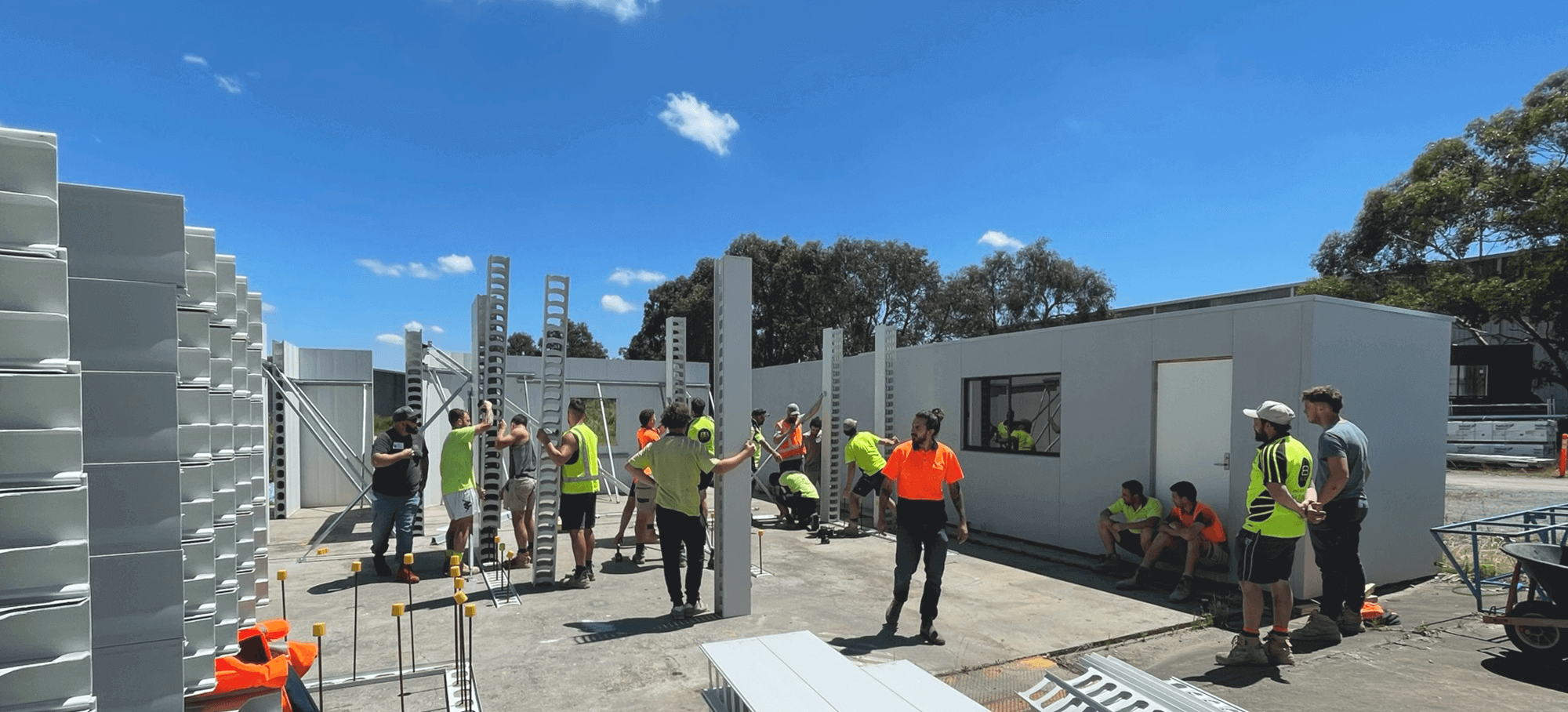

AFS permanent formwork systems are a smarter way to build compliant, concrete structural walls above and below ground.

AFS is part of the CSR Building Products group and is regularly specified with its product family, including Gyprock, Hebel and Cemintel.

Backed by CSR

Certified Australian-made

CodeMark Certified

our products

Maximise floor space, from basements to penthouses and everything in between.

AFS walls are used extensively across the detached residential, multi-residential, commercial, industrial, infrastructure, health, education, aged care, leisure and entertainment segments.

AFS Logicwall® is a fibre cement permanent formwork system, suitable for above ground applications such as stair shafts, balustrades, blade walls, internal party walls, corridor walls, façade walls, boundary walls and more.

Extensive product range

LW120 / LW150 / LW162 / LW200S / LW200D / LW262 mm

AFS Rediwall® is a permanent formwork walling system, suitable for above and below ground applications such as basements, blade walls, columns, party walls, retention tanks, retaining walls, landscaping walls, planter boxes, foundation walls, service and stormwater pits and more.

Extensive product range

RW110 / RW156 / RW200 / RW256 / RW275 / RW300 mm

Benefits Include

Speed of construction,

quick to install

Lightweight for easy handling,

not crane dependent

2-4 day delivery for

Rediwall stock orders

Free onsite support

and training

projects

CSR System Selector and CSR Thermal Calculator

Find the right system for your project.

Our digital tools help our partners and customers push the boundaries of what is possible in building. From selecting the right system for your project to understanding the thermal qualities of your walls, roof and floors, we empower confident decision-making throughout the construction journey.

resources

Access design guides, compliance documents and more for your building projects.

TESTIMONIALS

Hear why AFS is the smart choice for structural walls

Sam Stephens from Airworx Property Development speaks candidly about the benefits of using afs logicwall®

The afs logicwall system delivers on both fronts. We can be more accurate with our delivery of the product and keep clients up to date with reports. This helps bringing the project forward and saves time which means we're ahead of schedule and clients love this.

Ian McGivern speaks about the benefits associated with using afs logicwall®

The reason afs logicwall is more effective from a delivery point of view is the material handling is lower, the number of people required on site to install the product is less and the crainage required to lift the afs into place is lower. Delivery to site is alot more controlled, there is less material and less waste.

Ed Hanna from JSN Hanna discusses the many benefits of utilising afs logicwall®

The ease of working with afs logicwall is that you're able to put up a lot more product a lot quicker and the quality of finish is unsurpassed when you compare it to brickwork or cement render. The support from afs is one of the main reasons we keep going back to them from the drafting process, getting plans drawn up that are very accurate, panelling always delivered on site and on time.

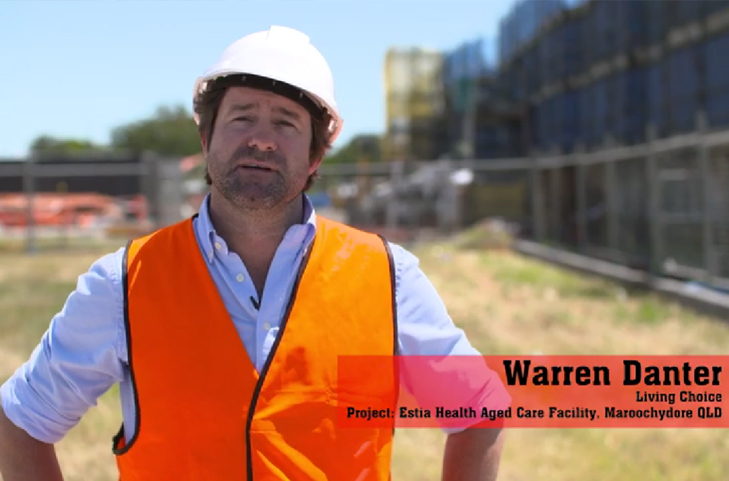

Warren Danter from Living Choice talks about why they chose afs logicwall® and discusses the many benefits logicwall®

Intially we had the design as block work load-bearing but due to delays through the planning stage we were two months behind the start date. I knew that afs logicwall was a very quick fast system so we implemented that and we've managed to catch up with the time that we lost.

![[14620] AFS curves ÔÇô GTM rollout Homepage banner AW](https://b2703846.smushcdn.com/2703846/wp-content/uploads/2023/05/14620-AFS-curves-OCo-GTM-rollout_Homepage-banner_AW.jpg?lossy=0&strip=1&webp=1)